The King Sewing Machine Company and the Domestic-King-Sears Connection

King Sewing Machine Company

The W G King Company

filed a certificate of incorporation in Buffalo, NY in 1906. The new company had $100,000

capital and the directors were W. Grant King, Charles F. Kilhoffer and William L Marcy. In February of 1908, they

changed the company name to

King Sewing Machine Company. W. Grant King was listed as president. King was a mechanical

engineer as well as an experienced manufacturing executive. They expected to manufacture 1000 machines per week

when their factory was completed.

By June of 1908, the new company

had increased capital stock to $250,000 and they had purchased numerous sewing machine

patents and planned to manufacture several models. Their factory at 254 Court Street was operating and they had

established a store at 630 Main Street and were showing samples of their sewing machines. They created an

elaborate catalog

with many clear images and instructions. By this time, Morris S. Tremaine was president and W. Grant

King was vice president and general manager.

The King sewing machine was reportedly manufactured with

modern industry standards with absolute

interchangeability of parts. They enlisted the help

of Frederick Miller

(some sources say Muller), a mechanical engineer with ten years experience designing automatic manufacturing

machinery for an unspecified big name sewing machine company. Miller

became a director

of King SMCo. In one

article, Tremaine was quoted as saying that Miller gave him the idea for getting into the sewing machine business,

so he started the King Sewing Machine Company. Miller had the nickname "Automatic Miller" for his genius in building machines.

A year and half was spent designing and building the machinery and gauges to make precisely machined,

interchangeable parts. Gauges used for quality control did not allow for variations over one thousandth of an

inch, or in some cases half a thousandth of an inch.

The company chose to manufacture vibrating shuttle

machines, which had been the in common use for decades, but

added their own (unspecified) detailed improvements. The first machines cost $33 and were sold directly from the

factory, through magazine advertising and mail order, as well as at the company store. The ad at left was in a 1908

Ladies Home Journal magazine. Note that the machine bed extends to the right of the pillar and the belt goes through the

bed. This is a very early version of the machine. They quickly changed it to be similar to other sewing machines where

the bed ended just tot he right of the pillar and the belt threaded through the cabinet instead of the machine bed.

In June of 1909, there were reports that President Tremaine and other Buffalo men joined with New York capitalists

in a “trust busting” effort to fight the mammoth

Singer Sewing Machine company. In that same month, the SMT

reported that King was looking for investors to increase production capacity.

The Sears, Roebuck & Co. Connection

In late 1909, King received a huge cash infusion of $250,000 from

Sears, Roebuck & Co.,

doubling their capital. Some reports said this was part of the trust busting scheme.

This deal reportedly included a

contract to take the

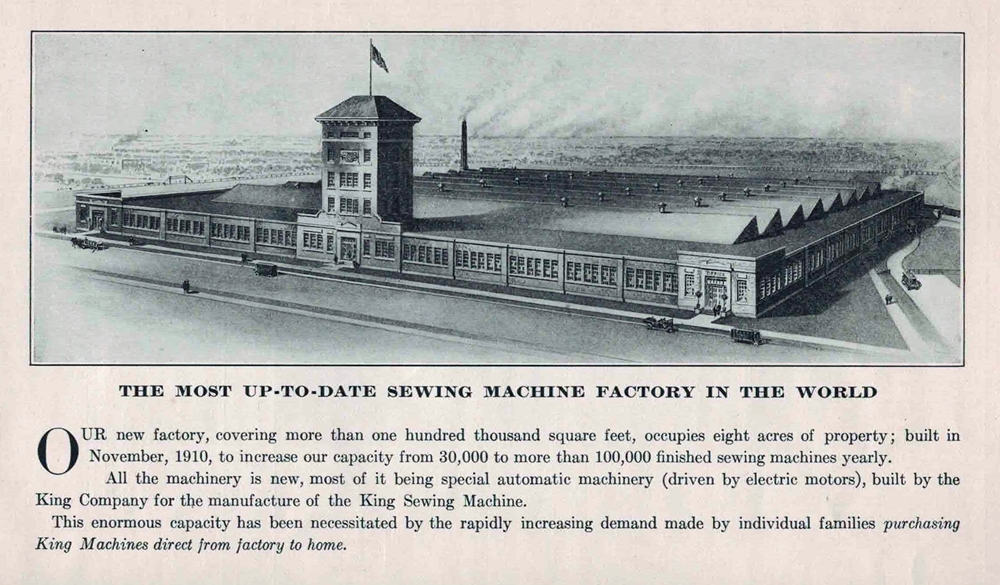

entire output of the factory. It was announced that King SMCo was building a huge new factory on Rano Street

in North Buffalo near the Lackawanna Railroad tracks. The company

leased

8 acres of land for ten years from Walter

H Schoellkopf, with the option to buy the land at the end of the lease. It was reported that "Chicago interests"

wanted the factory moved to Cleveland, but the

Buffalo men won out.

King requested that

three streets be closed because their factory buildings would be too big to fit between them. Two

thirds of the property owners on those streets signed a petition agreeing to this request, and this was granted.

The initial plan was to build three buildings, totaling 200,000 square feet and build a fourth building later.

At the time, the old King factory employed about 100 men, and the new one was expected to employ 500 to 600 men.

King requested that

three streets be closed because their factory buildings would be too big to fit between them. Two

thirds of the property owners on those streets signed a petition agreeing to this request, and this was granted.

The initial plan was to build three buildings, totaling 200,000 square feet and build a fourth building later.

At the time, the old King factory employed about 100 men, and the new one was expected to employ 500 to 600 men.

Plans

for the factory were filed in March of 1910. In April, King

contracted for construction

of a 250 foot by 450 foot building for $125,000. The factory

expanded

many times, both from new construction and buying neighboring businesses.

After a one day news splash on the day of the announcement of the Sears investment and the new factory being

built, their was little news in the papers about the King-Sears connection. In May of 1910, W. Grant

King wrote a letter

to the editor asking that they correct the misinformation being spread that King was

owned by Sears. However, at some point that changed because the

1920 Sears Consolidated Balance Sheet listed

the King Sewing Machine factory as completely owned by Sears. I checked all Sears annual reports from 1910

through 1923 and this is the only year where wholly owned factories were listed, and I have found no news

reports, so I can’t confirm when it happened. An article on the Needlebar website (no longer available)

stated that Sears bought King in 1915. I found this

article

from 1917 that describes King SMCo as one of the largest Sears factories in the country, making it sound like common

knowledge, so there must have been more news stories in the teens that I have not found.

King Made Sewing Machines for Sears, Roebuck & Co.

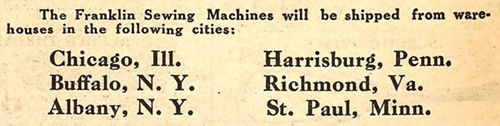

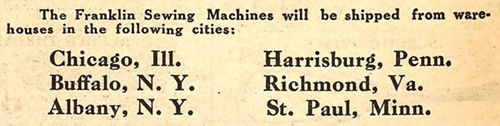

As explained above, Sears, Roebuck & Co. invested in King to have their own sewing machine supplier. It is

generally reported

that Domestic made a number of models for Sears, including the Franklin, Minnesota A and Minnesota H.

However, it is very unlikely that Sears would have bought the Franklin from Domestic starting in 1911 and the

Minnesota A from Domestic starting in 1913 when Sears either owned or essentially owned King SMCo at

the time. From 1910-1915, Domestic was owned by Foley & Williams, their factory was in Kankakee, Ill,

and they were in the process of going bankrupt for the third time.

In addition to the Franklin, Minnesota A and Minnesota H, King almost certainly made the Minnesota X.

Sears catalogs show that all the models credited to Domestic shipped from Buffalo, NY in addition to other warehouses.

The only other machines found to have been shipped from Buffalo are the Minnesota K and Elmore, which appear

to be hybrids of King and Davis machines. They did not ship from Dayton like other Davis-made machines. They remain

a mystery.

Please refer to

this page to see comparison photos between King, Franklin,

Minnesota and Domestic machines. Since 1908, King had been making a pretty close copy of a Singer 27. Starting in 1909, Domestic's flagship

model was the Domestic D, a fiddlebase machine bearing no resemblance to a Singer 27. Their only rectangular based models up until then were

the high arm of the 1860s and 1870s and the Domestic C and its clones of the early 1900s.

The Franklin and early Minnesota A are

very similar to the King VS.

There has been discussion on this topic with more supporting evidence on the Victorian Sweatshop forum

here and

here.

The Domestic Connection

As explained on the Domestic History page, Sears, Roebuck & Co. bought DSMCo when Domestic went bankrupt.

So, in 1915, Sears owned two sewing machine companies based in Buffalo. King had a huge modern factory and

Domestic had nothing but a name.

This is my evidence that Sears combined Domestic and King into one factory:

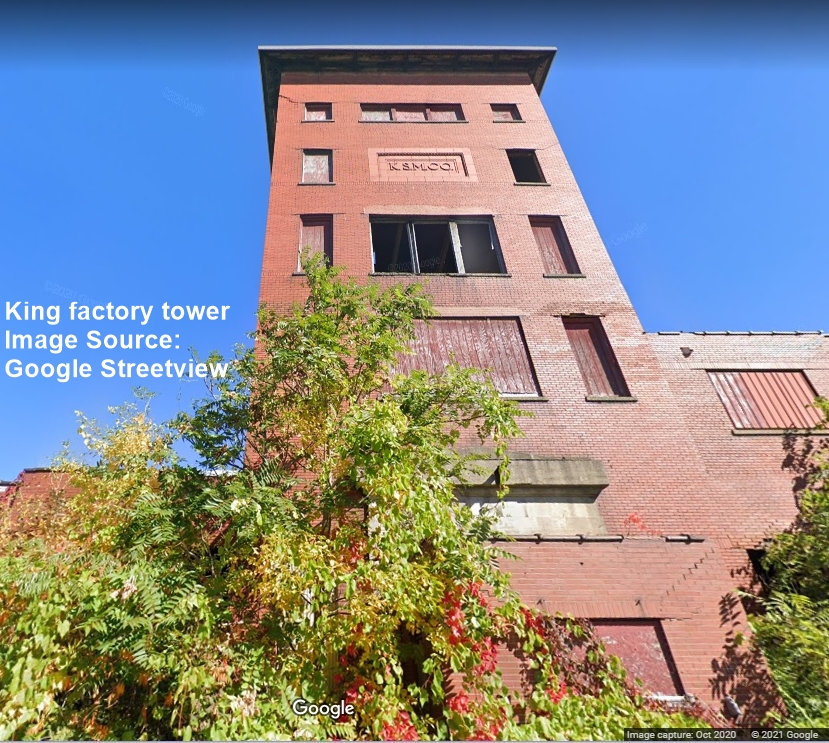

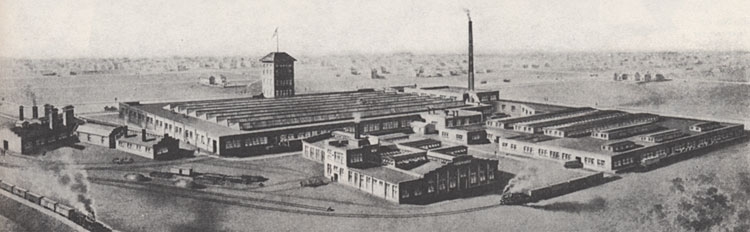

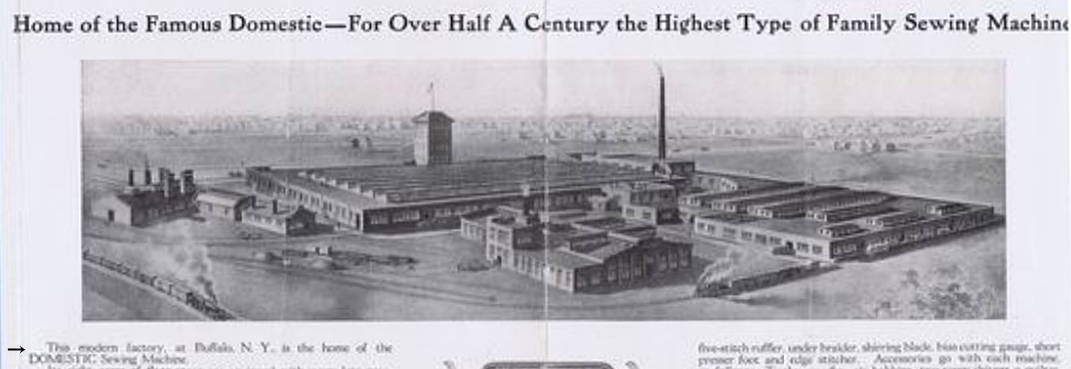

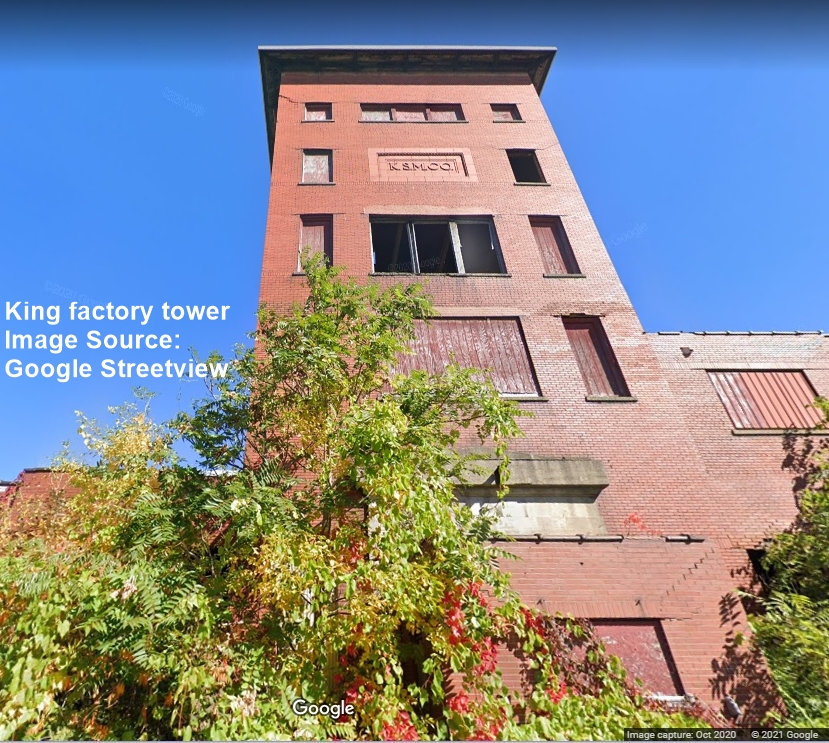

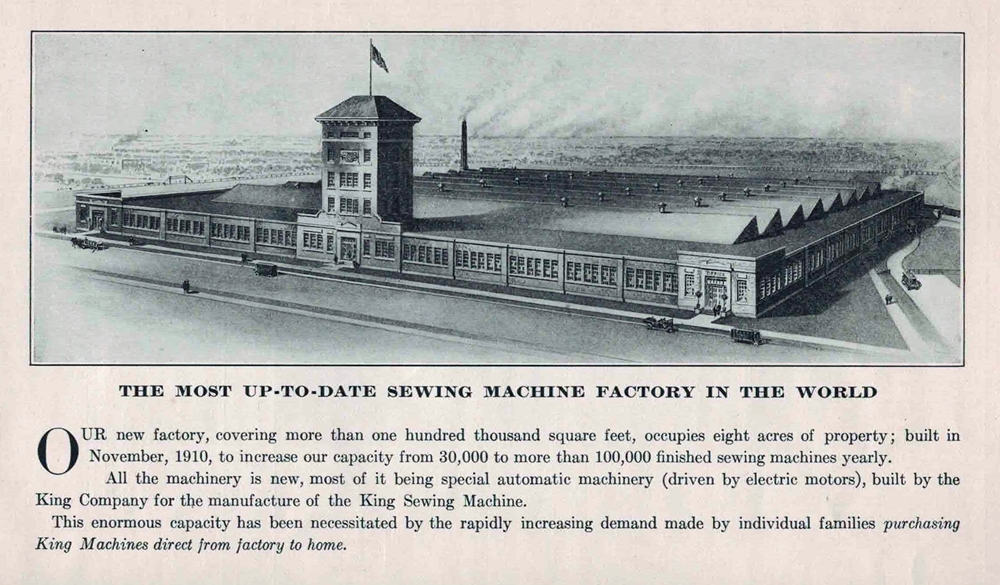

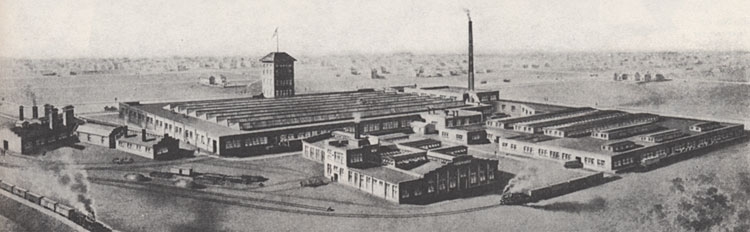

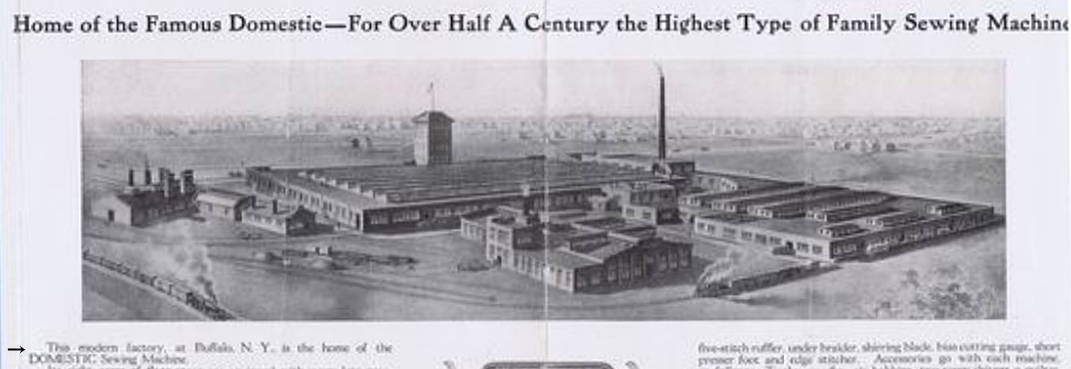

This image from a c. 1910 King booklet. It shows shows a distinctive central tower and a sawtooth roofline, with a tall smokestack

in the background.

This image from the back of a Domestic manual clearly shows the same factory.

King Factory, rear view: (Image source

wnyhistory.org)

Domestic ad:

In addition, this Google streetview image from 2020 shows the words Domestic Sewing Machines superimposed with King

Corporation on the side of the KSMCo tower.

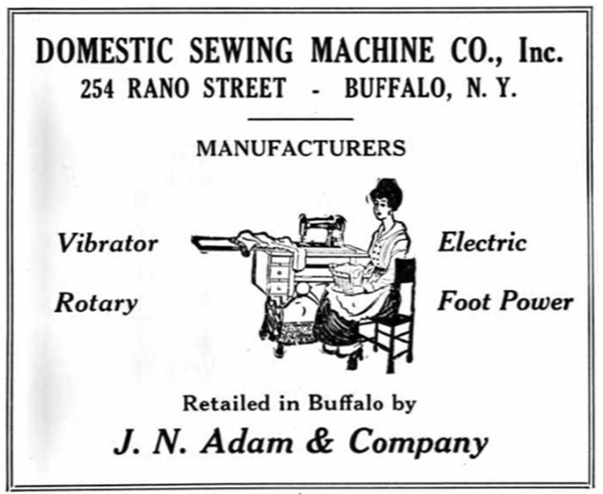

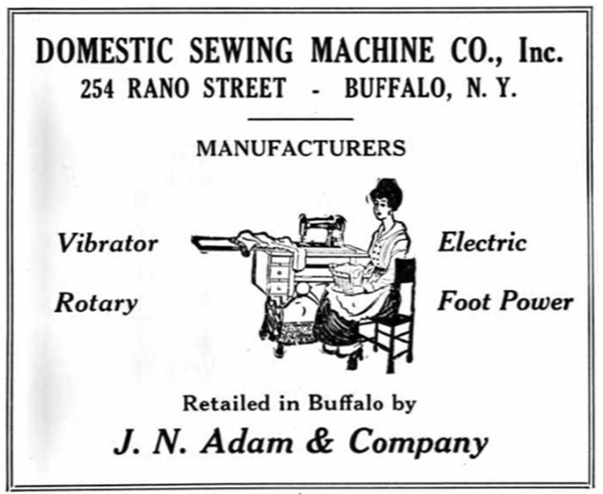

The ad at left from the

1920 Buffalo City Directory shows DSMCo, Inc, Manufacturers at 254 Rano Street.

The King Factory was around the corner (See map below).

In a

trademark application

filed March 2, 1918, DSMCo stated they were doing business at 254-298 Rano Street in

Buffalo, NY.

This

Federal Trade Commission report

on the home furnishings industry

in 1924 states that Domestic SMCo was a subsidiary of King SMCo and that Sears owned all of the King SMCo stock.

I think this statement

in the 1926 lawsuit may mean the same thing.

Conclusion

My conclusion is that Sears moved Domestic production into the King factory. I speculate that Domestic had

been around for 50 years and was a very well known name in the sewing machine industry, but King was a newcomer,

so they kept the Domestic name on most of the products. Despite early reports that Sears would buy the entire factory

output, King VS and rotary machines continued to be advertised at least until 1919, and of course there

were several much more well known Domestic and badged models that were made into the 1920s.

This helps to explain why the King factory had such enormous capacity but we don’t see nearly as many King

machines as Domestics of the same era. The factory was cranking out machines for Sears as well as Domestic labeled and badged

machines. It also explains little mysteries like the Lessing model that has King SMCo on the inspection plate but is advertised as

being “Domestic make” in newspaper ads.

Also the 8-10-1920 patent on The Minnesota A, Minnesota H, and New Willard slide plates is a King patent

(the only

King patent

I could find, in fact). New Willard has generally been accepted as

being a Domestic badge name, but there were ads in early 1915 advertising it as being made by King. The King

and Domestic machines were remarkably similar, but not identical.

I do not know how the two companies interacted in the factory. Domestic SMCo was still a separate entity to some extent,

but manufacturing was in the King plant. It seems unlikely that they would have separate manufacturing lines.

This page shows a comparison of models made by King and

Domestic in the 1910s and early 1920s. All of the VS models made in the King factory are very similar in appearance except

the Domestic Vibrator, which

has a more boxy shape. Perhaps that is the only true Domestic design and the rest are all King machines. All were made

in the same factory, but with Domestic being a separate company, maybe they had their own distinct model for some reason.

The Domestic and King Rotaries are also very similar.

King Factory Location

The King Sewing Machine Factory was described as being on on Rano Street in Buffalo, NY. Rano Street was terminated

to build the factory. The streets along the front and side of the factory were Weiland (now Crowley) and New (now Isabelle).

Below is a comparison of an arial view of the King factory in 2020 and a 1915 tax map. You can see that most of the

factory is still there, although it is in terrible condition as detailed in links below.

Notice the three railway spurs that run right up into the factory. You can still see traces of them in 2020.

Click for larger image

Click for larger image

Image sources: New York Public Library

Google Maps

In present day

street numbers, 254-298 Rano, the Domestic Manufacturing address in 1920, would be in the last building on the left

on Rano Street where it intersects with Crowley (formerly Weiland), highlighted by the dotted white box in the image at left.

This building is not shown on the 1915 map, which was made before DSMCo moved in with KSMCo.

Perhaps they built a new building to house the Domestic offices.

The solid white box highlights another addition made after 1915, and its shape coincides with the Domestic ad shown above which

has that area labeled "Domestic Sewing Machine Co (Inc?)".

Click here for close-up of that area of the ad.

The King Factory Today

This preservation website lists some of the history of

the factory since 1924.

Here is a

news report from october 2020 about neighborhood concerns about the decrepit and dangerous state of the factory buildings.

This article in February of 2023 shows that state of the King Factory at that time.

Here is an update on the King factory from June 2023. It looks like parts of it will be saved.

Photos of the factory taken in October of 2023 can be seen on

this page.

King requested that

King requested that

The ad at left from the

1920 Buffalo City Directory shows DSMCo, Inc, Manufacturers at 254 Rano Street.

The King Factory was around the corner (See map below).

The ad at left from the

1920 Buffalo City Directory shows DSMCo, Inc, Manufacturers at 254 Rano Street.

The King Factory was around the corner (See map below).